Makerfabs National Day & Mid-Autumn Festival Holiday Notice: 01/10/2025-07/10/2025

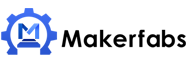

CL-32 Small Batch Custom PCBA

CL-32 Small Batch Custom PCBA

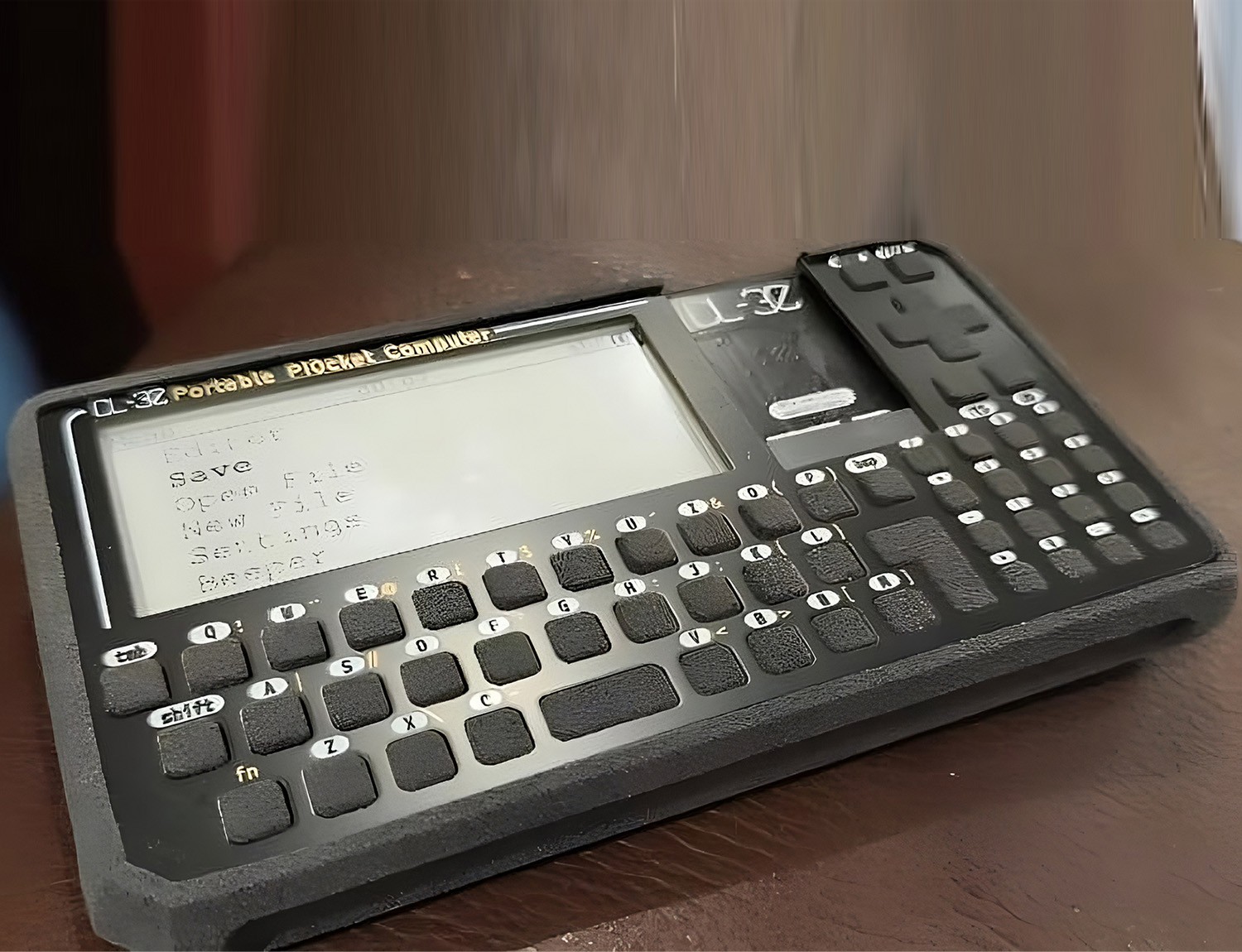

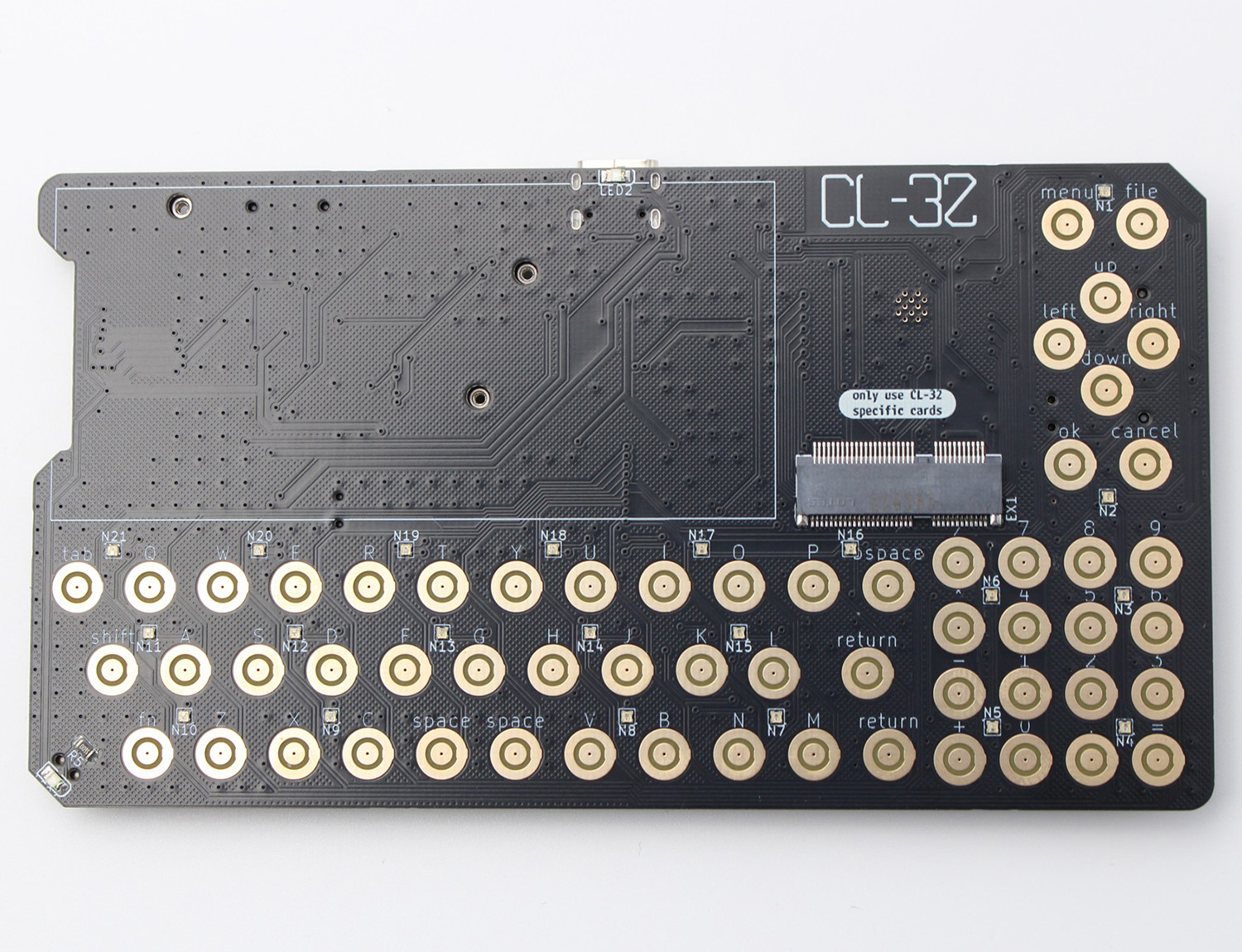

Custom PCB with Exposed Substrate — Small Batch, High Complexity: The CL-32 Case

Project Name

CL-32

Production Category

consumer

Cooperation Scope

PCBA Manufacturing/ PCB fabrication/Component sourcing/SMT assembly

Lead Time

3-4 Weeks

Country

United Kingdom

Quantity

15 pcs