How To Check The PCBA Quote From Shenzhen PCBA Factory

When the project comes to PCBA prototyping& small batch production, the Shenzhen factories are a good way to cost-down and also shorten the lead time.

Of course, the first step is sending the production-related files, include the PCB Gerber file/ specs, and the BOM list, together with the quantity, to the PCB factory for PCBA quotation. For the parts list, check the Tips in BOM when asking PCBA price. Normally, the factory will make a PCBA quote, based on:

1. PCB Cost;

2. Components;

3. Assembly Cost;

4. Others, such as Testing/ Programming/ shipping, or your customized services.

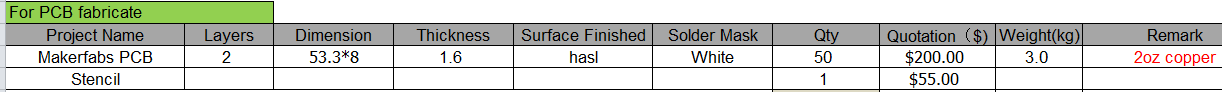

1.PCB Cost Quote

The PCB cost mainly depends on the PCB main spec and area. Besides, the PCB cost also depends on the PCB quality needs, which differs a lot.

1. If your PCB design simple(2/4 layer) and do not have detailed request on stack up& impedance control, and some mirror drawback acceptable, there some Shenzhen “Express PCB” works, the price really good and quality remain OK.

The price from JLC/ PCBway/ Seeed are good, they can even make the price to $0.99 for the most simple prototyping board (2 layers, small board). I do not know how could they make the price so low, this should be a business competition, to get more customers for further orders. For relatively larger quantity, the price depends on the final area, the unit price would be about $100/m2(including all the fees such as testing fee/ tooling fee) for 2 layers and $150/m2 for 4 layer board.

2. If your PCB design relatively complicated, more than 6 layers, or you have BGA designs/ blind vias/ impedance controlling, there the “express PCB prototyping” can not be used. They need to be built by a more “Industrial” PCB factory. There the price would be higher especially the starting fee. For a 2 layer PCB, the starting fee would be about $50, while maybe only $5 with “express PCB”. But the price difference got smaller as the quantity goes bigger... For an order total of 100 m2, the price would be almost the same.

3. You need to check with your PCBA factory the very detailed spec of the PCB spec, to avoid misunderstanding, includes:

● PCB Material: It would be a bad mistake if you want FPC but the factory quote/ produce with FR4.

● PCB Color: Normally it could be Green/ Yellow/ Black/ White/ Red, etc… The most popular used is Green... Personally, I like the Purple color, the OSH Park supports that with a good price.

● PCB layer: Sometimes, the inner layer with “Negative film” may be ignored, check if the factory got your all right, or it may lead to serious problems.

● Other PCB specs: Such as thickness(can be 0.6/ 0.8/ 1.0/ 1.2/ 1.6..), surface polishing, etc.

4. Lead time. Normally, for “Express PCB” prototyping, 2~3 days OK, while much longer with advanced PCB(normally >10 days) if urgently, ask them to ship the package to you with express shipping but not airmails... The shipping time could be 2~4 days from Shenzhen to any place in the world.

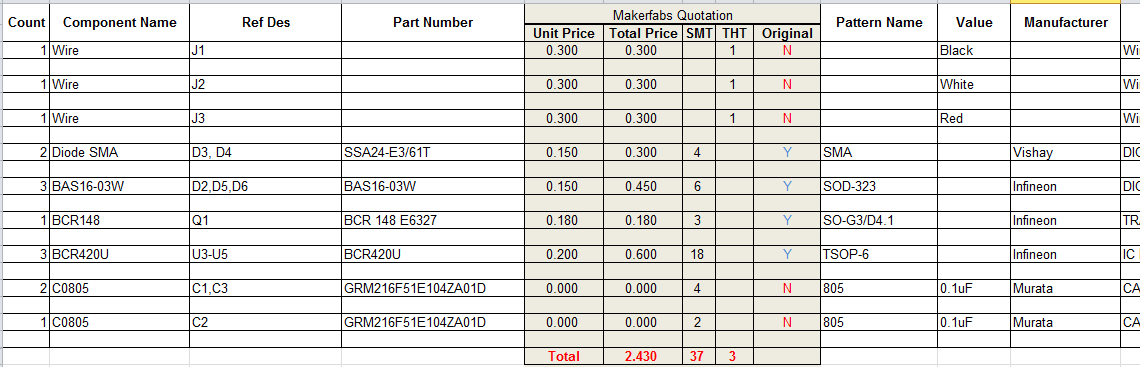

2. Components Quote

Double-check your BOM list before sending it to the factory(Again, check the Tips in BOM when asking PCBA price), and recheck every single component quotation, this does not only ensure you get them to get a reasonable price but also ensures the PCBA factory get you all right.

The factory will quote the components based on the quantity, normally, unit price drops a lot from small quantity prototyping to mass production, especially for some cheap connectors, the unit price for 1 pcs would be even 5 times that for 100 pcs. Check every rows quotation to estimate if the price acceptable:

1. For resistors/ capacitors, most of the factories will quote you as substitute items which should be very cheap(less than $0.01). But if you have a special request, for example, you need to use a 0.1% resistor, the price would be much higher. Check if the factory price reasonable, if they also quote it as $0.01, it should be them ignored this info, reminds them of your request. Of course, a part number would be a very good way for this.

2. Ask the factory detailed list if they will use the accurate item listed in your BOM or some substitute items. Such as a diode, it may be produced by many producers, if you need the ON brand but other brands may not work, you should check if the factory quote you all right.

3. For most factories, normally they will quote the IC original brand, while the passive component with substitute items if that not acceptable for you, ask them to update.

A final components quotation in PCBA quote shoul be like this:

3. Assembly Cost Quote

This is the core reason that PCBA produced in Shenzhen. Normally, the factory quotes the PCBA assembly as:

1. Starting fee. The starting fee depends on the soldering difficulty, including the quantity of the components/ double side or single side. Arrange from $20~$50 normally.

2. Most boards include the SMD soldering and THT soldering... For SMD soldering, the unit price drops a lot as the quantity increase, for example, for 50 pcs, the unit SMD soldering fee would be $10, while for 100 pcs, the fee maybe $7, and even $5 when it comes to 200 pcs.

3. For THT soldering, with small quantities, the factory may solder them manually, for bigger quantities, maybe wave soldering will be used, which will decrease the cost a lot.

But normally fixture needed for wave soldering.

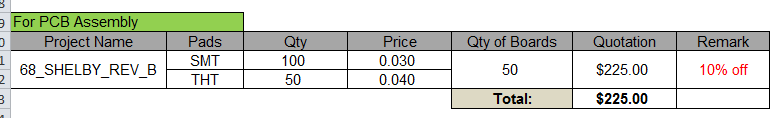

A final PCB assembly quotation in PCBA quote should be like this:

4. Other Cost: Testing/ Programming/ PCBA Coating/ Shipping

Besides, some factories can also help with programming/ testing such as Makerfabs. This is also the most important way to ensure the quality, you will not like to the bad working board on your desk.

1. Send them a detailed guide on the programming/ testing, and related files such as hex code. And ask them to prepare the related tools such as JTAG, normally, they should have the basic tools.

2. As the soldering completed, guide them to the first piece of programming/ testing, ask them to take a picture, or something, to prove the testing OK>/

3. Normally, the factor will quote this as the time needed, according to Shenzhen worker salary, $0.1~$0.2 per minute.

4. If any other special requests such as coating/ protecting, try to explain to make your PCBA factory understand clear.

5. And of course, the shipping, for small packages lower than 3kg, the registered airmail would be OK, much cheaper but lead-time longer, 10~20 days; and for less than 200kg, the express shipping such as DHL is a good solution; for higher weight, maybe ocean shipping should be considered...

Finally, you got the final PCBA quote from the Shenzhen factory (Download "Makerfabs PCBA Quotation"), a tip, try to bargain with them if you think you can win... As the payments, for customized boards, the factory will need you to pay for them in advance, if not a big deal, using Paypal would be a safe way for you; But for larger payment( such as$5000) it is not a good solution using Paypal as the high transaction fee, a compromise way to ensure safety for both sides is partial payment in advance, depends on you& your factory trusty to each other.

If you need an agile and reliable PCB assembly service and small batch production vendor in China, pls feel free to contact us at service@makerfabs.com for a PCBA quotation.

Previous

Previous