SMT Assembly Service Capability

As a turnkey PCB assembly service vendor, Makerfabs provide SMT assembly services for small batch PCBA prototyping and mass production. Get your first PCBA order with 50% off!

SMT (surface mounted technology) is currently a popularly used technology in the PCBA manufacturing process. Electronics components are picked and placed directly onto the PCB surface by machine. Why SMT become so popular?

1. Advantages of SMT

(1) High density, small size, and lightweight of electronic products. The volume and weight of SMD components are only about 1/10 of traditional through-hole components. Generally, with SMT assembly, the electronic products’ volume is reduced by 40%~60%. The weight is reduced by 60%~80%.

(2) High reliability and strong vibration resistance. Low solder joint defect rate.

(3) Good characteristics in high frequency. Reduce electromagnetic and radio frequency interference.

(4) Automated PCBA manufacturing by machine, with high production efficiency, save material, time, and labor, can reduce cost by 30%~50%.

2. Makerfabs SMT Assembly Capability

As a turnkey PCB assembly service vendor, Makerfabs with rich experiences in electronics manufacturing, we provide SMT assembly services for small batch PCBA prototyping and mass production, our production facilities can assemble the following SMT types:

● 0201/ 0402/ 0603/ 0805/ 1206

● BGA (Ball Grid Array) > 0.3mm Pitch

● uBGA (Ultra-Fine Ball Grid Array)

● QFP (Quad Flat Package)

● QFN (Quad Flat Pack No-Lead)

● SOIC (Small Outline Integrated Circuit)

● PLCC (Plastic Leaded Chip Carrier)

● PoP (Package-On-Package )

● Small Chip Packages (pitch of 0.2 mm)

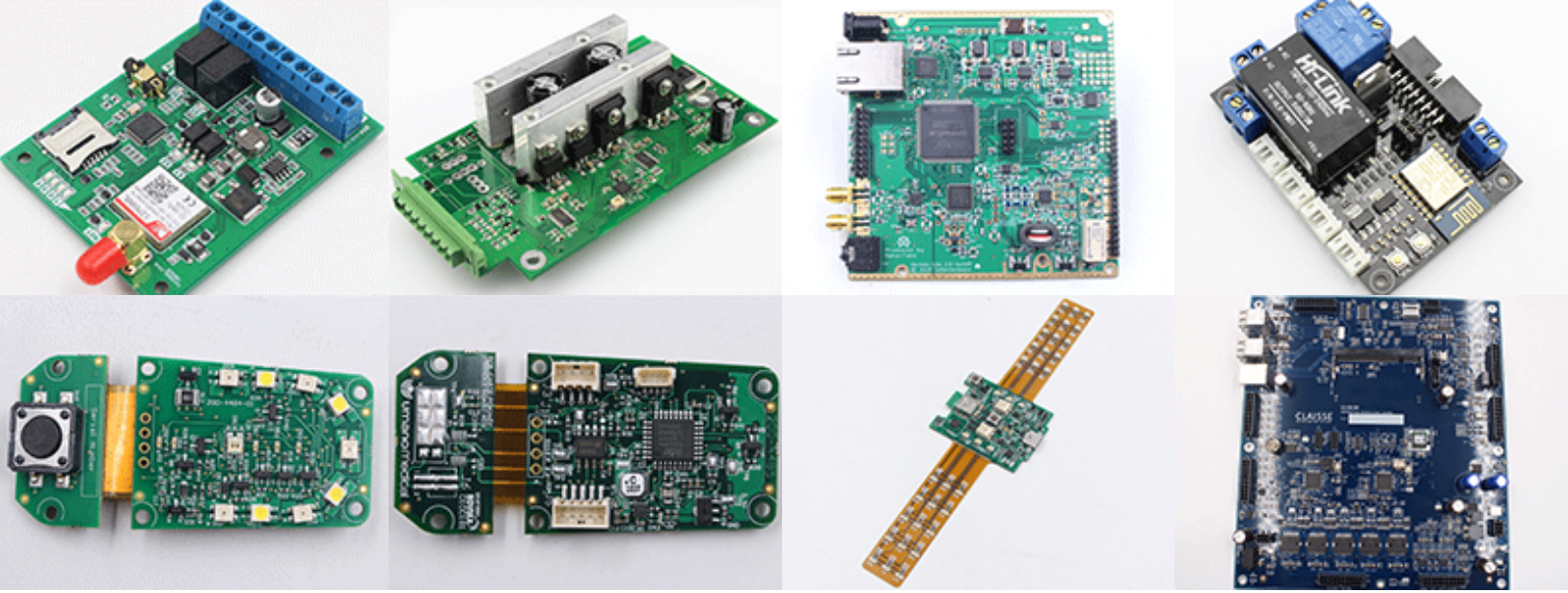

Below are some PCBA boards manufactured by Makerfabs.

@Dear makers,

Contact us now for your first PCBA order, you can get a discount up to 50%!Also, you can check on Makerfabs EMS service page.

Previous

Previous