Why WS2812 SK6812 Failures after SMT Soldering

Why WS2812 SK6812 Failures after SMT Soldering?

This is an old blog posted on Makerfabs blogger in 2018, it seems many people encountered the same problem, so Makerfabs decided to publish it again and hope it can do some help for more people who are doing related WS2812/SK6812 LEDs projects.

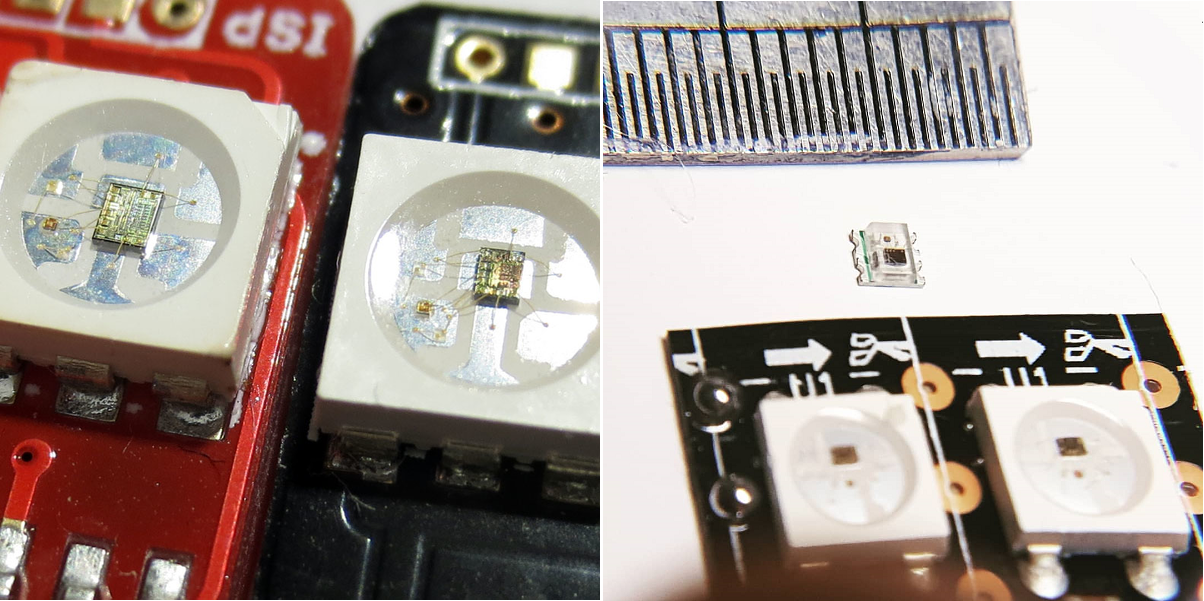

1. Overview: The WS2812 LED do not on as intended in the PCBA production

Makerfabs encountered an SMT soldering problem in a small batch PCBA production: the WS2812/SK6812 Failures, What's the problem and how to avoid this kind of problem?

There so many WS2812 LEDs used, most of them are soldered on a separate board for display. Many makers use the WS2812 LED in their own projects, but, no one will tell that there a big mistake in your PCBA prototyping& small batch production.

Yes, you will get an astonishing failure rate, after the reflow soldering as this man:

"So recently, I and another fellow from work ordered some of these WS2812's (neopixels) from Adafruit. We ordered them loose, so we could build our own boards here in our shop and run them through our reflow oven. We use pneumatically dispensed solder paste and a conveyer style reflow oven. The reflow curve is calibrated frequently and does not exceed 250 degrees Celsius. Upon testing the WS2812's, approximately 30 percent of the LED's had failures (missing R or G or B LED diode)."

Makerfabs encountered an alike problem, that we found almost all the WS2812 LED do not on as intended, really nightmare:

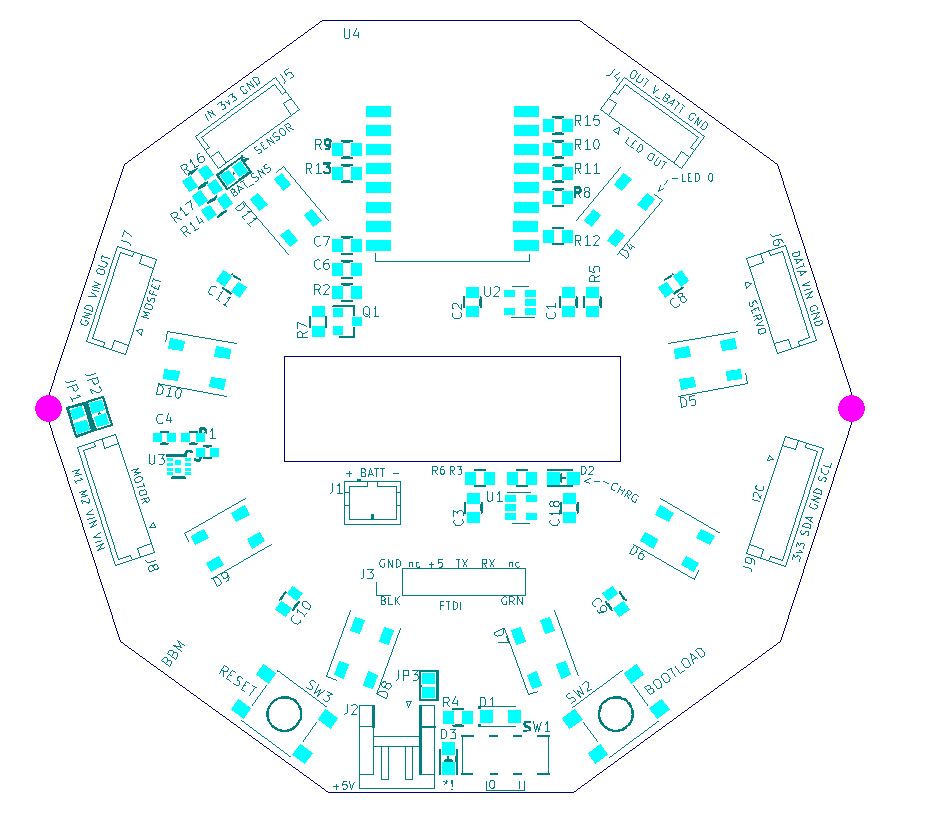

This is one of our customer’s design, 16 pcs of WS2812 LEDs are serially connected to the controller module ESP12. If any LED got destroyed, all the LED follow will not be on as the 1 wire communication protocol.

The result is: There're 120 pcs PCBA produced, and almost NONE of them works.

2. Why this happened and how to solve it?

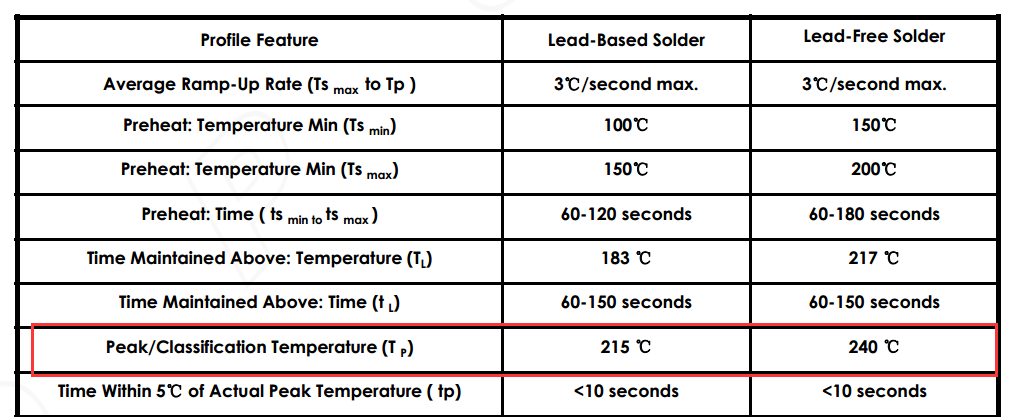

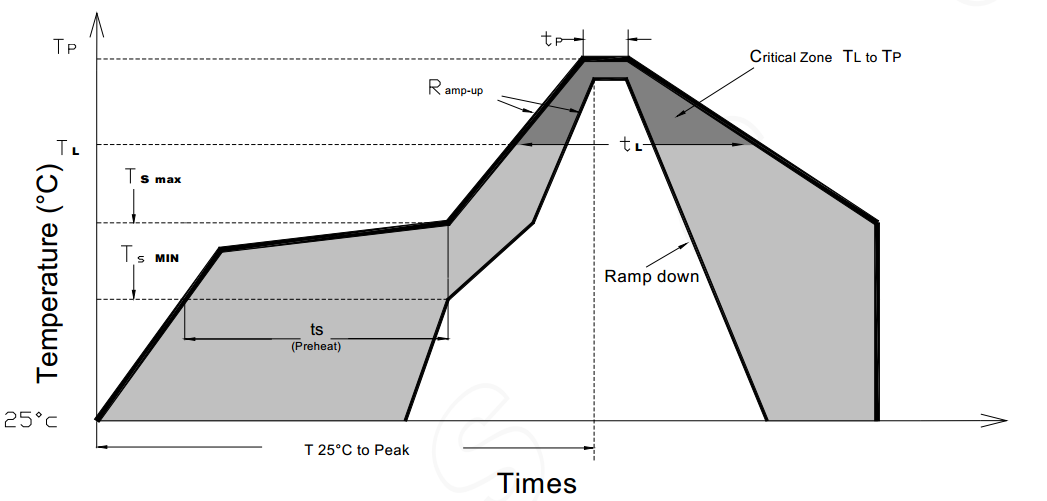

The LED quality problem? Seems NO. We checked some sample new LED, all works. After checking the datasheet, the datasheet shows us: soldering temperature: 240 °C, and indeed our soldering temperature is 240°C ~!

Without any other solution, we asked the WS2812 producer, they feedback us: the soldering temperature suggested is < 230 °C... And the Medium temperature solder paste suggested.

Got ~ The datasheet bad. Normally, to ensure the SMT soldering quality, especially for components that are tall, the High-temperature solder paste would be safer to keep the soldering quality. But for the WS2812 LEDs, or alike LEDs SK6812, high-temperature solder paste, which needs a soldering temperature >240 °C, will lead to serious damage to the LEDs.

3. Makerfabs’s suggestion on WS2812/SK6812 LED design& soldering:

1. Using the Medium temperature solder paste, to ensure the soldering temperature <230 °C;

2. Do not use height components, such as SMD electrolytic capacitor, together with WS2812/SK6812 LEDs on the same boards. The SMD electrolytic capacitor soldering temperature needs to be high, which will lead to LED damages, unless you will solder them manually.

4. Related problems in Makerfabs PCBA production

It's true that we will meet all kinds of problems in PCBA production, such as:

Solving The OLED Sticking Problem;

Solving The Soldering Problem;

Solving The DDR Connector Problem.

Makerfabs will try best to solve them and keep sharing those kinds of experiences with makers/ engineers. If you have other good suggestions, open to let us know. Contact us at service@makerfabs.com for PCBA related requirements.

Previous

Previous